Views: 268 Author: Tina Chen Publish Time: 2018-04-26 Origin: Site

The first step is the design phase of the slewing bearing.

The first step is the design phase of the slewing bearing.Advanced calculation techniques attuned to slewing bearings guarantee an economic and safe dimensioning of load transmitting and of components in which deformation is a critical factor. This new method allows a highly economical solution as well as from the mechanics point of view a very realistic analysis of the overall system of slewing bearing and companion structure.

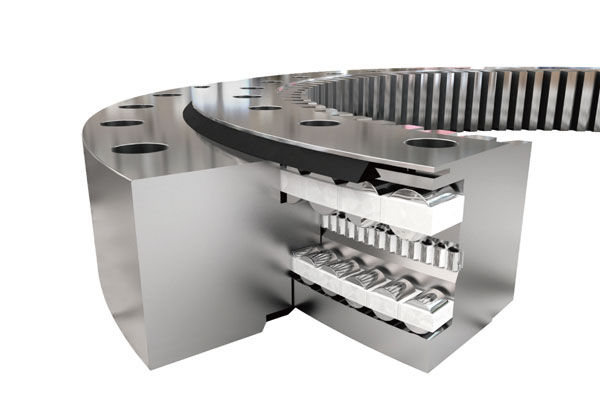

The production of the slewing bearing.

Then follows the production of the ring forgings in the plant.

After that, the finish-rolled ring is transported to the plant for further machining and treatment.

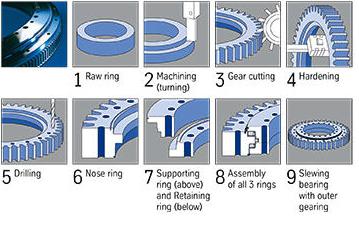

Slewing bearing - Manufacturing process

1- Raw ring, 2- Machining (Turntable), 3- Gear cutting, 4- Hardening, 5- Drilling, 6- Nose ring, 7- Supporting ring (above) and Retaining ring (below), 8- Assembly of all 3 rings, 9- Slewing bearing with outer gearing

Fire Drill and First Aid Training Conducted by Xuzhou Wanda Slewing Bearing Co., Ltd.

The Surface Treatment of Slewing bearings: Painting, Zinc spraying, Zinc Plating, Nickel Plating.

Introduction of Protection Level of Spur Gear Slewing Drive and New Slewing Bearing

Xuzhou Wanda slewing bearing successfully delivered a 5 meters slewing bearing for floating crane

Anti-rust advice for stocked slewing bearings of XZWD company

Home | About Us | Products | News | Application | Support | Contact Us