Views: 27 Author: Site Editor Publish Time: 2020-08-20 Origin: Site

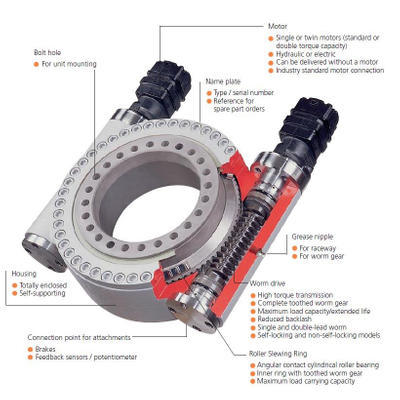

The slewing drive is an important part used in many construction machinery nowadays, because of its utilization rate and importance, so it will be damaged in use. As a key part of the main engine, whether the rotary drive device can work properly is related to the performance of the main engine. The cold winter weather will have a certain impact on the normal operation of the slewing drive. For users, it is important to prevent damage of slewing drive, so how to extend the life of slewing drive?

· lithium grease

· Drive and Control

· Investigation and management of hidden dangers

1.A small amount of lithium-ion 2 grease is applied inside the slewing drive unit when it leaves the factory, so the user should refill the new grease according to different working conditions;

2. should be comprehensive work factors, users can also choose the best grease according to specific requirements; grease shall be added regularly to the raceway of the

3. Grease should be added regularly to the raceway of rotary drive device. The general ball support is refueled once every 100 hours of operation, and the roller support is refueled once every 50 hours. The lubrication period should be shortened in special working environment. New grease must also be added before and after the machine stops running for a long time. Each lubrication must fill the raceway with grease until it seeps out from the seal strip. When the grease is injected, turn the slewing drive slowly to make the grease fill evenly;

4. Teeth should also be cleaned and greased.

1. To install the deceleration motor, clean the mounting surface Connect the adapter flange and tighten the screws between the deceleration motor and the slewing drive.

2. Connect the AC or DC power to the motor and check the rotation by changing the direction to adjust the clockwise or counterclockwise direction Motor connections.

3. Rotate the motor without load to ensure its smooth rotation.

4. If not rotate, check the current whether grease exists inside the system, joint flange and slewing drive.

5. Add rated load after successful completion of load free test.

1.Bolts shall be checked after the first 100 hours of operation of the slewing drive and sufficient pretightening force shall be maintained for each 500 hours thereafter.

2. In use, pay attention to the operation of the slewing drive device, such as noise, impact, power suddenly increased, should immediately stop to check, troubleshooting, if necessary to remove;

3. It is forbidden to wash the slewing drive directly with water in winter to prevent ice and snow from entering the raceway. To prevent hard foreign bodies from approaching or entering the dentate zone;

4. Always check the seal intact condition, if found seal bag broken should be replaced in time. If found shedding should be reset in time.

Home | About Us | Products | News | Application | Support | Contact Us