Views: 1 Author: Site Editor Publish Time: 2026-01-31 Origin: Site

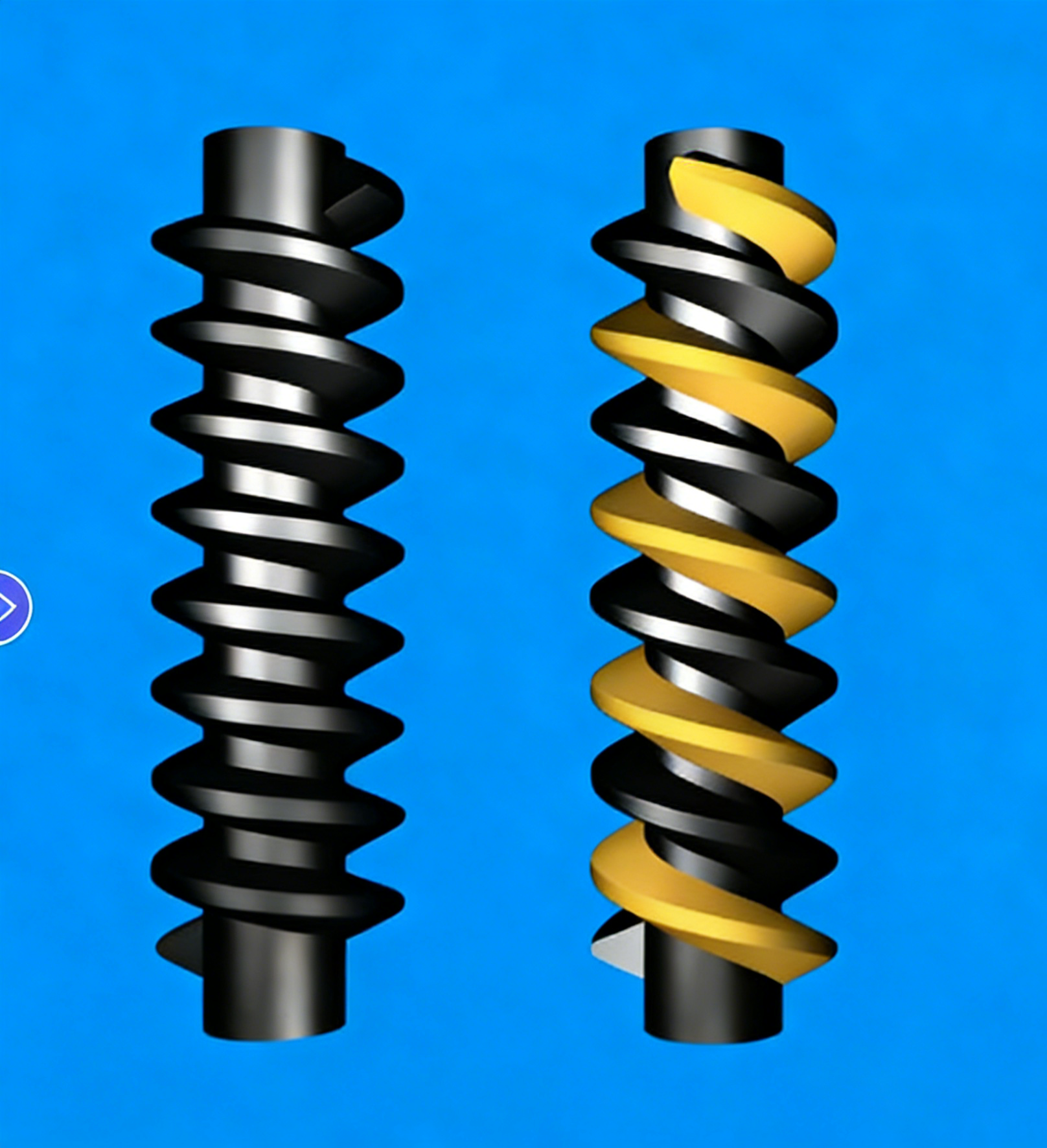

Different number of spiral threads: A single-start worm has only one spiral thread on the worm shaft, while a double-start worm is equipped with two opposing spiral threads on its shaft.

Different number of worm rotation cycles: One full rotation of a single-start worm drives the worm gear to rotate by one tooth, whereas one full rotation of a double-start worm makes the worm gear rotate by two teeth.

Different stress under rotation: When a double-start worm rotates, its two spiral threads disperse the stress more evenly, enabling it to bear a larger load.

Different transmission efficiency: A double-start worm features higher transmission efficiency. This is because it can mesh with the worm gear at two contact points simultaneously during transmission, which reduces frictional losses in the drive system.

Different machining difficulty: The production of a double-start worm requires more sophisticated manufacturing processes and higher machining precision, making its processing more complex.

Different precision levels: A double-start worm has higher precision. This is due to the fact that a double-lead worm gear pair can operate with a smaller backlash, which is highly conducive to improving the indexing precision of CNC rotary tables.

Advantages of double-start worm: Rotational speed can be doubled; Disadvantages: No self-locking function

Home | About Us | Products | News | Application | Support | Contact Us